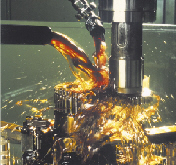

Neat cutting oils

Neat cutting oils for every industrial need

INUSTRY controls and provides you with a wide range of whole cutting oils through brands adapted to each type of need:

- INUSTRY

- UNITECH

Industry

Compatible with most metals, DIABIX whole oils® CUT are intended for machining, milling, turning, cutting, grinding operations, etc.

Get in touch

.

Discover DIABIX whole oil® CUT PLAST 12, specially designed for plastics machining.

Whole oil for plastics machining: DIABIX® CUT PLAST 12

Neat oil for machining plastics

DIABIX® CUT PLAST 12 is a transparent synthetic oil, made from a base specially selected for the formulation of high-end machining oils.

DIABIX® CUT PLAST 12 is intended to be used for machining operations on plastics or other special non-ferrous materials.

Advantages of DIABIX oils® CUT PLAST 12

- Excellent rinsing property

- Free from heavy metals, zinc and chlorine compounds

- Excellent cooling property

- Low fog formation

- No color alteration of sensitive materials

- Very good anti-foaming behavior

Characteristics of DIABIX whole oils® CUT PLAST 12

- Density at 20°C: 834 kg/m3 (ASTM D 4052 method)

- Kinematic viscosity: 12 mm2/s (ASTM D 445 method)

- Flash point: 170°C (ASTM D 92 method)

- Shelf life: 24 months (from -10°C to +40°C)

Data provided for advisory purposes, for guaranteed data, please refer to the Safety data.

Neat oil for deep drilling

Optimize your deep metal drilling operations with the performance of LPC oils.

DIABIX® CUT LPC 506: whole oil for machining / drilling by removing steel and non-alloy chips

DIABIX® CUT LPC 506 is used for deep drilling using the BTA process, the 1-lip drill process or the ejector process. The composition includes synthetic fatty substances, partly sulfurized esters and phosphorus additives. This combination of active substances makes it possible to obtain very long tool lifes as well as good surface quality.

properties:

- Very good surface qualities

- Excellent tool life

- Harmless mineral oils according to IARC

- Very good cooling effect

- Very good anti-foaming behavior

- Excellent flushing and chip evacuation properties

Features:

- Density at 20°C ASTM D 7042 864 kg/m3

- Kinematic viscosity at 40°C ASTM D 7279 10 mm2/s

- Flash point ASTM D 92 140°C

- Parts machined with FORAGE 506 can be cleaned without residue in solvents and detergents from the INUSTRY range.

- Shelf life: 24 months at +10°C/+40°C

MSA LPC 600: high-performance synthetic oil based on GTL (Gas-To-Liquids) oils

properties:

- Very good surface qualities

- Excellent tool life

- Free from heavy metals, zinc and chlorine compounds

- Very good cooling effect

- Very good anti-foaming behavior

- Excellent rinsing properties

- Low mist formation thanks to the use of GTL oils

- High viscosity index

Features:

- Density at 20°C ASTM D 7042 840 kg/m3

- Kinematic viscosity at 40°C ASTM D 7279 13 mm2/s

- Flash point ASTM D 92 155°C

- Parts machined with FORAGE 600 can be cleaned without residue in solvents and detergents from the INUSTRY range.

- Shelf life: 24 months at +10°C/+40°C

Data provided for advisory purposes, for guaranteed data, please refer to the Safety data.

unitech

German manufacturing partner, specialist in industrial technical fluids, UNITECH has extensive experience in metalworking. It combines skills, innovation and power to offer high-performance, customer-oriented solutions for each industrial process, in accordance with HSE requirements.

MMS Neat Cutting Oil

The refrigerating lubricants of the MMS range, immiscible with water, have been developed especially for the use of MQL techniques. Designed for use in a multitude of applications, MMS oils stand out for their high material compatibility and high performance. Based partially on renewable resources, they are appreciated by users and respectful of the environment. The use of materials combined with innovative active substances reduces consumption and guarantees economical use.

MSA Neat Cutting Oil

The MSA range of cooling lubricants, immiscible with water, have been developed for use in metalworking operations, with or without chip removal. Particularly efficient, these oils improve the surface condition of parts and the lifespan of tools. They are characterized by their very good stability and are very appreciated by users. The use of materials combined with innovative active substances reduces consumption and guarantees economical use.

Services

Equipment intended for optimizing cutting fluid

See Fluid Management Equipment